Aerospace Plastic Injection Molding

Aerospace Plastic Injection

Flexi Mould : Professinal Company of Aerospace Plastic Injection Molding in India!

It’s well-known that specialized fields like military and aerospace demand stringent material and technical standards. The plastic materials employed must exhibit high strength, temperature resistance, mechanical strength, and excellent toughness.

Creating components for aerospace applications necessitates proficiency in plastic mould manufacturing and strict adherence to regulatory requirements for high-quality mould standards. Regardless of whether the aircraft is intended for commercial or defense use, TDL has the capability to bring your aerospace parts to life.

Take flight with Flexi Mould Plastic Mould

Flexi Mould provide high-quality, precision-engineered plastic and metal components,

leveraging advanced injection molding and CNC machining techniques to deliver

superior performance for your aerospace products.

Component Design and Engineering Assistance

Our expert team customizes and optimizes your aerospace components, offering 3D-printed plastic parts, traditionally-manufactured components, and CNC machined metal parts, all tailored to your specifications and material requirements for optimal performance and quality.

High-Quality Aerospace Component Materials

Our plastic engineers follow the universal AS9100 (BS EN 9100) quality management standard for the aerospace industry, which involves using materials including plastic composites, titanium, powdered metals, and more for injection molding and CNC machining. Most plastic composites we use are PC, PA, PEEK, PEAK, LCP, PI, ABS and etc.

Advanced and Traditional Manufacturing of Aerospace Parts

FLEXI MOULD is equipped with a range of mold making equipment and injection molding production equipment to support precision mold manufacturing and complex products production. We have traditional manufacturing and additive manufacturing capabilities for earospace products with exacting specifications.

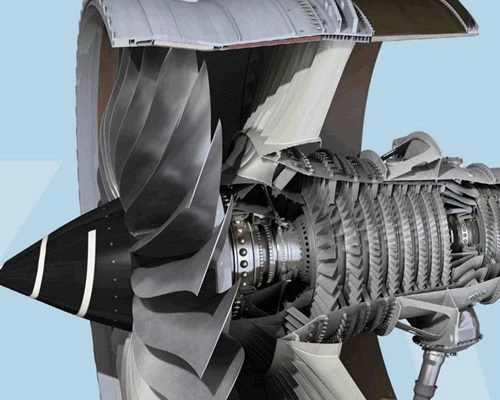

Common Aerospace Applications

We’ve produced aerospace applications that meet today’s strict industry needs.

Here’s what we can make with you:

Lighting System

Turbines and Gears

Sockets and Conectors

Door Components

Aircraft Interiors

Why Choose Flexi Mould?

Experience, Expertise, and Excellence :

The Advantages of Choosing TDL Engineering Solutions.

20+ Years Experience

For over 20 years, Flexi mould has excelled in creating plastic tools for the automotive, medical device, and electronics industries.

Advanced Equipment

Flexi Mould is equipped with advanced mold manufacturing equipment and precision measuring instruments CMM.

On-Time Delivery

Flexi Mould schedule every mold projects manufacturing process very well, can guarantee on-time delivery for each production.

Professional Team

Flexi mold design & engineering team has 34 skilled engineers to provide technical support for plastic mold making and plastic processing.

One-Stop Solution

Flexi Mould offers one stop solution to meet customers all demands about plastic mould and customized plastic products manufacturing.

After-sales Service

Flexi Mouls is responsible for quality of each mold, will sign mold quality warranty with customers for every tools.

Custom Injection Molding Solutions at Flexi Mould

Your trusted partner in providing high-quality custom injection molding solutions. We specialize in offering advanced manufacturing services, including plastic injection molding supplier, to meet the diverse needs of various industries. TruMould is committed to delivering precision, consistency, and efficiency in every project we undertake.

25 Years of Experience in Mold Making Company

Welcome to Flexi Mould, a leader in high-quality metal steel for injection molds and premium resin for plastic parts manufacturing. Our dedication to excellence and innovation drives us to provide superior products and services tailored to meet the diverse needs of our clients across various industries.