Capabilities

Product Design

TDL Mould Capabilities

Located in Morbi, India,Flexi Mould, LTD has been a trusted global provider of mold-making services since 2021.Our ISO9001 certified team of over 180 professionals employ HASCO, DME, and LKM standards, along with advanced CAD/CAM/CAE systems, to deliver top-tier services. Our core offerings include:

Product Design

Flexi Mould’s experienced product design team collaborates intimately with clients to define and optimize design specifications, balancing technical, economic, and aesthetic aspects to meet end-user needs.

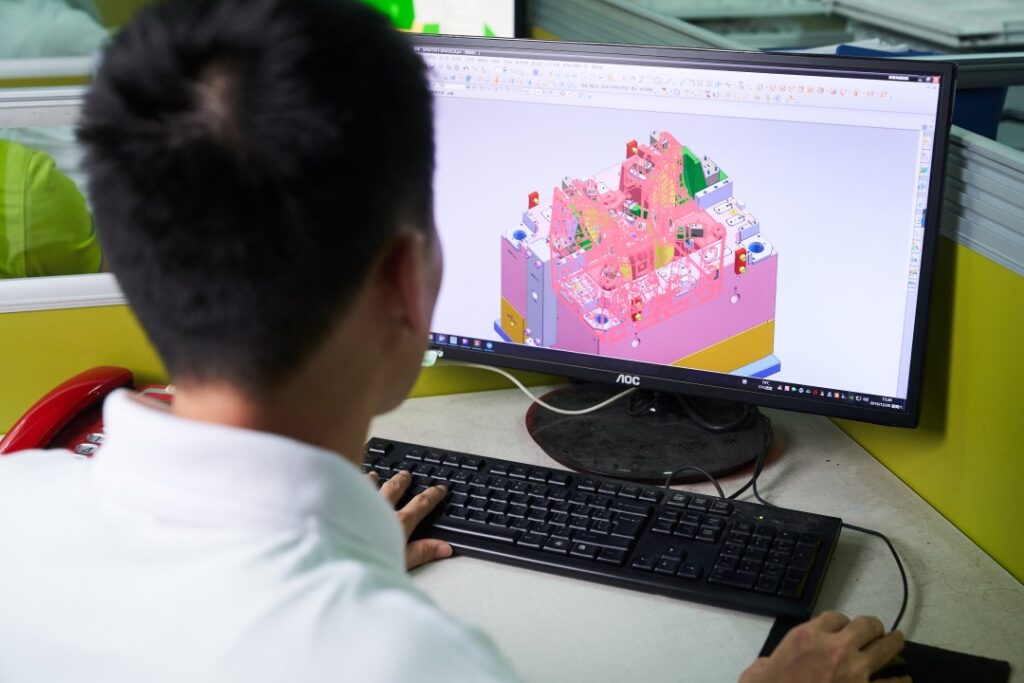

Mold Design

With years of expertise, Flexi Mould creates custom molds, ensuring alignment with client’s design goals and manufacturing requirements, using the latest technology for maximum efficiency and durability.

Mold Manufacturing

Flexi Mold enhances quality and productivity in custom mold and product manufacturing through rigorous engineering, addressing molding issues and optimizing design and tool production efficiency.

Plastic Injection

Flexi Mould offers cost-effective, high-volume plastic injection molding, creating high-quality parts for diverse industries, with specialized services like ISO8 cleanroom production for the medical sector.

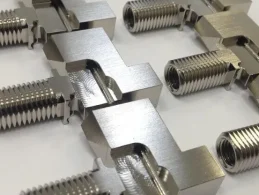

CNC Machining

In CNC Machining, Flexi mould employs advanced machinery to fabricate precise components directly from CAD files, offering high precision, repeatability, and compatibility with a variety of materials.

Rapid prototyping

Flexi Mould’s rapid prototyping techniques, including CNC Machining, 3D Printing, Vacuum Casting, and Silicone Overmolding, swiftly and accurately materialize innovative designs.

3D Printing

3D printing technology to create intricate parts directly from digital models,

providing quick turnarounds, design flexibility, and cost-effective

low-volume production

Surface Finishing

Flexi Mould offers diverse surface finishing techniques for functional or aesthetic purposes on CNC machined metals, injection-molded plastics, and fabricated sheet metal, considering factors like material, color, texture, and cost.

Why Choose Flexi Mould?

Experience, Expertise, and Excellence :

The Advantages of Choosing TDL Engineering Solutions.

20+ Years Experience

For over 20 years, Flexi mould has excelled in creating plastic tools for the automotive, medical device, and electronics industries.

Advanced Equipment

Flexi Mould is equipped with advanced mold manufacturing equipment and precision measuring instruments CMM.

On-Time Delivery

Flexi Mould schedule every mold projects manufacturing process very well, can guarantee on-time delivery for each production.

Professional Team

Flexi mold design & engineering team has 34 skilled engineers to provide technical support for plastic mold making and plastic processing.

One-Stop Solution

Flexi Mould offers one stop solution to meet customers all demands about plastic mould and customized plastic products manufacturing.

After-sales Service

Flexi Mouls is responsible for quality of each mold, will sign mold quality warranty with customers for every tools.

Custom Injection Molding Solutions at Flexi Mould

Your trusted partner in providing high-quality custom injection molding solutions. We specialize in offering advanced manufacturing services, including plastic injection molding supplier, to meet the diverse needs of various industries. TruMould is committed to delivering precision, consistency, and efficiency in every project we undertake.

25 Years of Experience in Mold Making Company

Welcome to Flexi Mould, a leader in high-quality metal steel for injection molds and premium resin for plastic parts manufacturing. Our dedication to excellence and innovation drives us to provide superior products and services tailored to meet the diverse needs of our clients across various industries.