Consumer Products

Plastic Injection

Flexi Mould : Professinal supplier of Consumer Products

As lifestyles evolve, the demand for lightweight and convenient consumer electronics is on the rise. Plastic, with its lightweight, highly malleable properties, low production cost, and functional versatility, is increasingly utilized in the production of these goods. This trend necessitates a reliable partner proficient in contemporary injection moulding technology and advanced manufacturing processes for plastic consumer product manufacturers.

Flexi Mould, a leading supplier of plastic tools, is renowned for its consistent quality, innovation, and specialization in creating plastic injection moulds for consumer electronics and product components. We’re committed to delivering exceptional results tailored to your needs.

Common Consumer Products Applications

Flexi mould is a premier plastic tool supplier for exceptional quality consistency and innovation.

We specialize in plastic injection mold making for consumer electronics and products plastic components or parts

Plastic Products

Prototyping Support

Surface Finishing

Products Testing

Product Assembly

Why Choose Flexi Mould?

Experience, Expertise, and Excellence :

The Advantages of Choosing TDL Engineering Solutions.

20+ Years Experience

For over 20 years, Flexi mould has excelled in creating plastic tools for the automotive, medical device, and electronics industries.

Advanced Equipment

Flexi Mould is equipped with advanced mold manufacturing equipment and precision measuring instruments CMM.

On-Time Delivery

Flexi Mould schedule every mold projects manufacturing process very well, can guarantee on-time delivery for each production.

Professional Team

Flexi mold design & engineering team has 34 skilled engineers to provide technical support for plastic mold making and plastic processing.

One-Stop Solution

Flexi Mould offers one stop solution to meet customers all demands about plastic mould and customized plastic products manufacturing.

After-sales Service

Flexi Mouls is responsible for quality of each mold, will sign mold quality warranty with customers for every tools.

Scope of Services

Experience unparalleled quality and innovation with Flexi Mould, your trusted partner

specializing in crafting exceptional plastic injection moulds for consumer electronics

and product components.

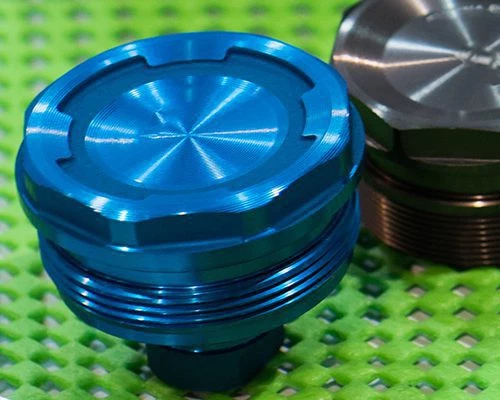

Consumer Products Design and Manufacturing

We analyze the functional requirements of consumer electronics and products to determine the most suitable manufacturing technology; We support clients from design, rapid prototyping, and manufacturing. We have a strong plastic mold engineering team to help creating efficiencies in both the plastic mold making process and the plastic injection molding process about the consumer products.

Quality Management and Certifications

Our plastic mould engineering & manufacturing team have established a quality control management to support plastic mold manufacturing. QC, QA workers control quality according to quality management procedure. For injection molded parts, we have CPK test for plastic parts production and products manufacturing. And our factory is under ISO9001 management, quality of plastic products and molds are guaranteed.

Finishing, Assembly and Delivery

We help clients do plastic injection molding, molded parts finishing like painting, silk printing, laser engraving, electroplating, anodizing, sand blasting and etc. We also support plastic products assembly and packaging for clients. We have three stable logistics suppliers cooperating with Flexi Mould for more than 10 years. Our logistics partners support us to arrange freight in time and goods deliveried to customers safely on time.