Medical Plastic Injection Molding

Plastic Injection

Flexi Mould : Professinal Company of Medical Plastic Injection Molding in India!

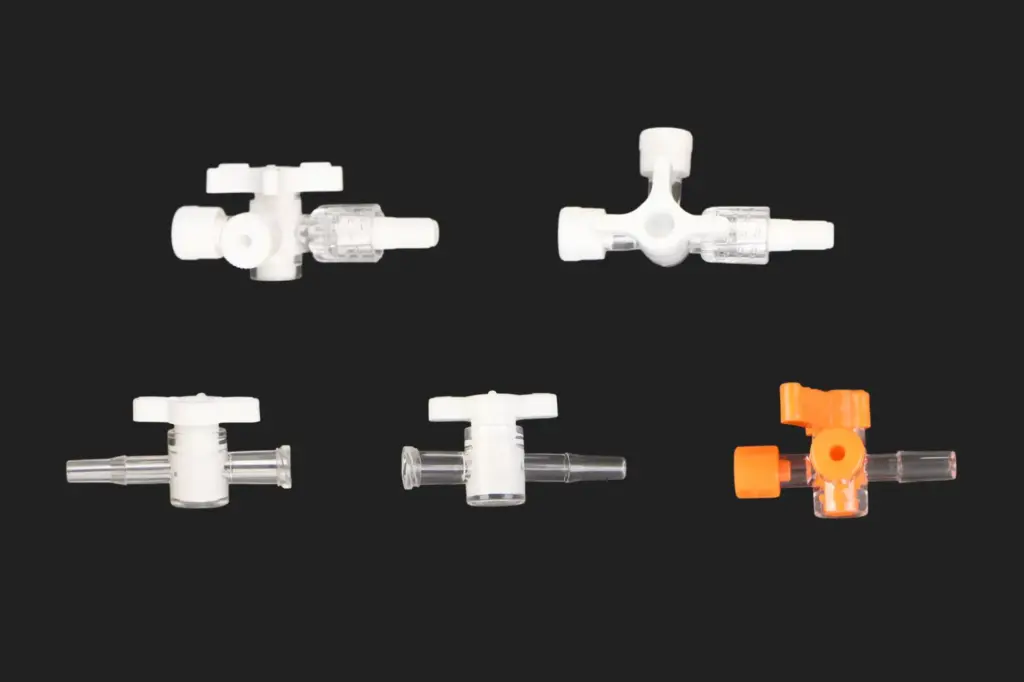

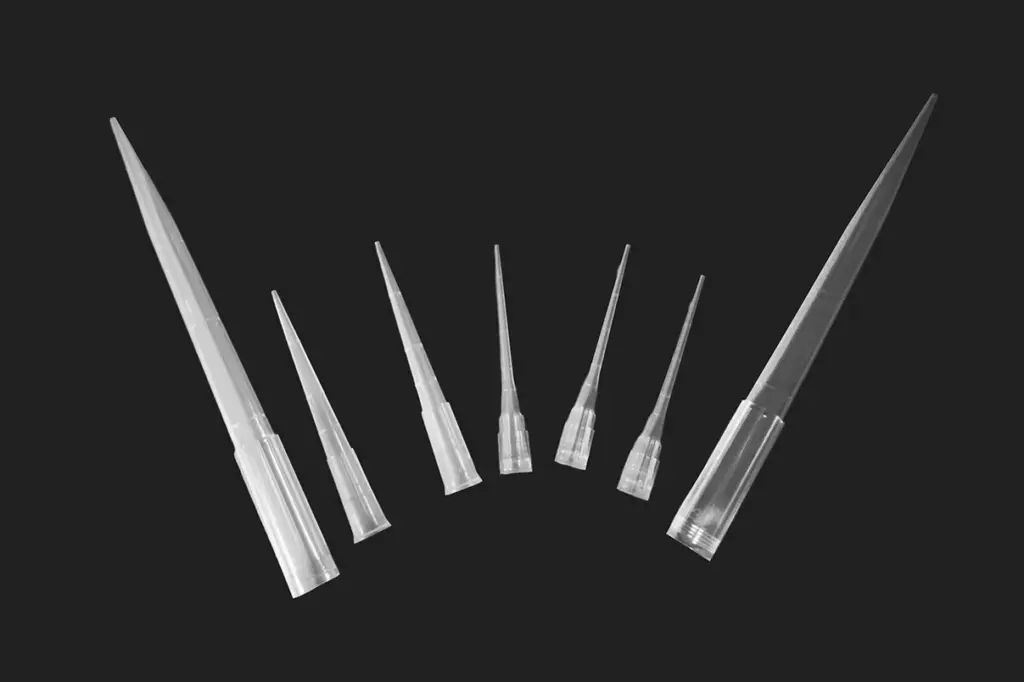

Medical and laboratory technology plastic molded parts necessitate stringent hygiene standards and advanced injection molding production techniques. The injection molds employed in production utilize only top-quality raw materials and mold components, leading to an increasing demand for innovative sliding coatings. Furthermore, most medical products, such as tips and luer tubes, necessitate clean room injection molding.

Special requirements also exist for mold maintenance, inspection, cleaning, and storage. The mold steel used in medical device production must be rust-resistant stainless steel. The risk assessment, validation, quality control, and product production of injection molds for medical and laboratory technology make them more costly than standard plastic molds.

Flexi Mould Company, however, stands out in this field. Equipped with a 100,000 class (ISO8 level) dust-free injection molding workshop, TDL is well-positioned to assist medical manufacturers with production. Crucially, TDL supports the injection molding production of PVC plastic molded medical products in a clean room environment, demonstrating its commitment to meeting the highest industry standards.

What products have we made?

TDL Mold has created a range of innovative products for the medical industry.

Common Medical Applications

Explore the world of healing with TDL: Your trusted partner for medical applications.

Medical Disposable

Life Science Product

Beauty Equipment

Medical Instrument

Medical Devices

What are our advantages in the medical industry?

Experience, Expertise, and Excellence :

The Advantages of Choosing TDL Engineering Solutions.

Certified

Flexi Mould is a certified mold manufacturer with a strong track record of quality and performance.

Mold Acceptance

Flexi Mould conducts mold acceptance tests to ensure that the molds meet the customer’s requirements before shipping them out.

Provide CPK Test

Flexi Mould provides CPK (Process Capability Index) tests to ensure that the injection molding process is capable of producing products that meet the customer’s specifications.

Medical Grade Plastic Materials

Flexi Mould uses medical grade plastic materials for molds that are used in medical applications, ensuring that all products meet the highest standards of safety and effectiveness.

Production Environment Cleanliness Requirements

Flexi Mould meets strict production environment cleanliness requirements to ensure the highest level of quality for each mold.

Good After-sales Service

Flexi Mould is responsible for quality of each mold, will sign mold quality warranty with customers for every tools.

Our Equipment

CNC Machining Workshop

Plastic Injection Molding Room

High Speed CNC Machines