Surface Finishing

Surface Finishing

Flexi Mould : Professinal Company of Surface Finishes in India!

Flexi Mould offering a multitude of surface treatment technologies for various products. For CNC Machining Metals, we offer a range of finishes including Brushed, Bead blasted, Powder coated, Black oxide, Electroless Nickel Plating, and Bead Blasted + Anodized type II. When it comes to Injection Molding Plastics, we cater to different aesthetic and functional requirements with finishes such as Glossy, Semi-glossy, Matte, and Textured.

As for Sheet Metal Fabrication, our offerings extend to Anodizing, Bead Blasting, and Powder Coating techniques. Our commitment lies in delivering top-notch surface treatment solutions tailored to your needs, ensuring both durability and aesthetic appeal.

Available Surface Finishes for You Choosing

Part surfacing finishing techniques can either be for functional or aesthetic purposes. Each technique has requirements, such as materials, color, texture, and price. Below are the specifications of the plastic finishing techniques rendered by us.

CNC Machining Metals

Powder coated

Powder coating is a strong, wear-resistant finish that is compatible with all metal materials.

Bead blasted

Parts are bead blasted with glass beads which results in a grainy texture and reduced machining marks.

Black oxide

Conversion coating applies a matte black magnetite layer on a material by immersing it in a hot chemical solution, followed by rinsing and oiling to secure the surface.

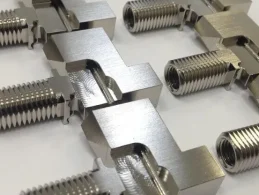

Electroless Nickel Plating

A wear and corrosion resistant surface is achieved by depositing a nickel-phosphorus alloy on a material without using electricity. The resulting surface is hard, slick, and highly conductive.

Brushed (Ra 1.2μm / Ra 47μin)

It creates a linear pattern with a consistent and uniform texture on your part’s surface. Suitable for architectural components and automotive parts.

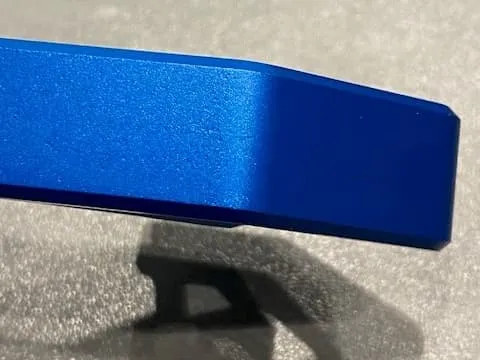

Bead Blasted + Anodized type II (Glossy)

Parts are bead blasted, anodized type II and bright dipped. Results in glossy color. Ideal for cosmetic parts needing an increase in corrosion resistance.

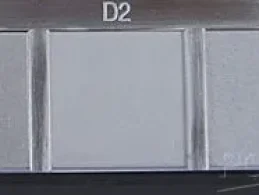

Textured

D1, D2, and D3 grade treatments use dry blast glass beads, and oxides for the surface finish to produce a very coarse and textured surface.

Matte

The C1, C2, and C3 SPI grade surface treatments use grit sanding stones to achieve rough texture and uneven surface.

Semi-glossy

The SPI standard B1, B2, and B3 grade surface treatment uses grit sandpaper paper to yield a semi-glossy surface finish.

Glossy

The SPI grade A1, A2, and A3 surface finishes are made with diamond buffing for a glossy and shiny surface finish.

Injection Molding Plastics

Sheet Metal Fabrication

Electroplating

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Powder Coating

To create a robust and uniform coating, dry powder is applied to the material and baked at high temperatures. This process endows the parts with superb resistance to corrosion, chipping, and fading. Depending on the type of powder, the texture of the coating can be either glossy or matte.

Bead Blasting

Bombarding a material’s surface with tiny glass beads or ceramic particles results in a uniform, matte finish that can eliminate surface imperfections and machine marks while simultaneously improving the part’s resistance to wear and corrosion.

Anodizing

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Why Choose Flexi Mould?

Experience, Expertise, and Excellence :

The Advantages of Choosing TDL Engineering Solutions.

20+ Years Experience

For over 20 years, Flexi mould has excelled in creating plastic tools for the automotive, medical device, and electronics industries.

Advanced Equipment

Flexi Mould is equipped with advanced mold manufacturing equipment and precision measuring instruments CMM.

On-Time Delivery

Flexi Mould schedule every mold projects manufacturing process very well, can guarantee on-time delivery for each production.

Professional Team

Flexi mold design & engineering team has 34 skilled engineers to provide technical support for plastic mold making and plastic processing.

One-Stop Solution

Flexi Mould offers one stop solution to meet customers all demands about plastic mould and customized plastic products manufacturing.

After-sales Service

Flexi Mouls is responsible for quality of each mold, will sign mold quality warranty with customers for every tools.

Custom Injection Molding Solutions at Flexi Mould

Your trusted partner in providing high-quality custom injection molding solutions. We specialize in offering advanced manufacturing services, including plastic injection molding supplier, to meet the diverse needs of various industries. TruMould is committed to delivering precision, consistency, and efficiency in every project we undertake.

25 Years of Experience in Mold Making Company

Welcome to Flexi Mould, a leader in high-quality metal steel for injection molds and premium resin for plastic parts manufacturing. Our dedication to excellence and innovation drives us to provide superior products and services tailored to meet the diverse needs of our clients across various industries.